In today's fast-paced manufacturing environment, efficiency isn't just a goal—it's a necessity. Whether you're prototyping a new product, scaling up for production, or managing tight turnaround times, every second counts. That’s where CamdenBoss’s Easy Assembly Enclosures come in—designed with your time, budget, and productivity in mind.

Getting more out of your enclosure

11/11/2020Selecting an enclosure after designing and positioning all of your components onto your PCB can be a difficult task. It can present hurdles that, in many circumstances, require you to make compromises on some features of the enclosure. As a UK based world-leading manufacturer of electronic enclosures, this is something that we wish to alleviate to ensure our customers are able to select an enclosure that matches as many of their requirements as possible.

The most common compromise we experience at CamdenBoss is the enclosure’s overall size. Often, after a PCB has been designed, the designer will need to find a suitable enclosure to ensure the PCB is not obstructed and any connectors are able to protrude freely from the side of the enclosure. This can lead to choosing a slightly larger enclosure than first anticipated as most enclosures have internal pillars that are needed as screw points for attaching the lid.

But what if there were an enclosure that completely resolved this issue?

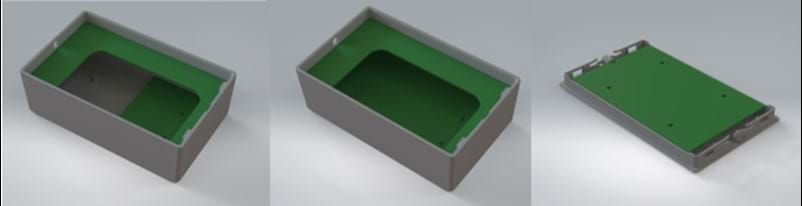

CamdenBoss’ experienced and innovative design team has resolved it with their latest enclosure, the Easy Assembly Electronics Enclosure. Amongst its many useful features and benefits is the maximised PCB footprint, providing complete edge to edge capability. This has been achieved through the lid’s unique design, removing the need for pillars, therefore freeing up the internal space. The fact that there are no internal pillars allows your PCB to meet at a 90 degree angle in every corner and for it to sit flush at every edge, maximising the internal space to its full potential.

So how does this benefit you?

Ultimately, this revolutionary manufacturing technique provides you with an enclosure solution that openly accepts your pre-designed PCB in a variety of positions, without any, or very limited compromise compared to other electronic enclosures on the market. You are able to freely customise the enclosure to suit your component positioning in an orientation that suits you. Not only will you face no obstructions to your PCB, the Easy Assembly Electronics Enclosure makes use of a series of PCB supports that are positioned around the edges of the enclosure, ensuring your PCB is secured and supported right up to the edges.

So, why else would you select this enclosure over others available on the market?

As previously mentioned, internal pillars can mean you have to select an enclosure larger than you require, incurring increased costs for a larger electronic housing. With the Easy Assembly Electronics Enclosure there are no obstacles for your PCB and you can select an enclosure that fits like a glove, thereby reducing your bill of material costs. What’s more, the practical nature of this enclosure, with its engineered details, keeps giving to you as the user. The incorporated fast assembly features speed up time on the assembly line and provide additional cost savings due to efficiency.

The smart use of space and designed features is what you can expect from the Easy Assembly Electronics Enclosure, where every aspect has been thoroughly designed and included to make the user experience one to remember. You can find out more about this innovative new enclosure by visiting our website www.camdenboss.com/easy-assembly-electronics-enclosure or by getting in touch with our sales team on 01638 716101 to discuss your requirement today!

Connect.

Enclose.

Innovate.

For further information on products please contact our Sales Team:

Alternatively visit our distributors page to find your nearest stockist or download the latest CamdenBoss catalogues.